Company Profile

DEKUMA Rubber and Plastic Technology (Dongguan) Ltd is the international well-known solution provider of rubber and plastic processing technologies. DEKUMA provides total solution for customers on turn-key basis.

DEKUMA, formerly known as Dongguan DEKUMA-WELLTEC Machinery Ltd, was a joint-venture between Cosmos Machinery Ltd (a wholly owned subsidiary of the HK publicly listed Cosmos Machinery Enterprises Limited) and German Dekuma Gmbh. DEKUMA specializes in developing, producing and selling rubber injection machine and extrusion line; it is dedicated to provide total solution including machine, mould, downstream and auxiliary equipment to customers world-wide. DEKUMA renamed as DEKUMA Rubber and Plastic Technology (Dongguan) Ltd in 2009.

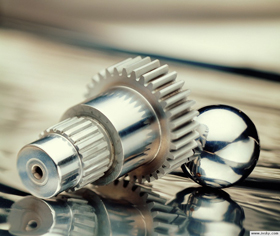

Our products strictly uphold European standard with their main parts such as injection unit, extrusion unit, screw and die head leaded by German technology and raw materials chose and processed firmly according to German standard, which guarantee high quality and reliability of our products.

With our sophisticated technology and professional service, DEKUMA is committed to maximize value for customers and to become the leading brand of rubber and plastic machinery in the world.

DEKUMA was accredited by ISO9001 quality system, CE certification and UL certification. We strictly control raw material and equipment inspection by formulating related files and introducing advanced inspection equipment such as carbon and sulfur analyzer, spectrograph, etc.

DEKUMA is equipped with 400 sets of processing equipment, 30 sets of large-scale processing equipment and 10 sets of flexible high precision machining center. Our company adopts volume production as planned to greatly improve production efficiency and save production cost. DEKUMA applies SOLIDWORKS software to design and other professional software to do finite element analysis. By leeching on to the purchasing platform of the Group, DEKUMA is able to buy high quality products with the most favourable price.

There are more than 30 professional research personnel in DEKUMA; 50% employees in the company have bachelor degree; at the same time, DEKUMA, with specialized academician workstation, has established long-term cooperation with South China University of Technology.

We export our products to America, Germany, Italy, Canada, Austria, Brazil, Morocco, Columbia, India, Indonesia, Iran, Saudi Arabia, Iraq, Egypt, Russia, Japan, and Vietnam.

Our products are featured with the advantages of advanced technology, high output, and complete automatization. The key parts are designed by German experts, which make our products rank first in domestic market.

Our rubber injection moulding machine is used for processing rubber products by melting and injecting rubber into die cavity and finally molding through vulcanization. The machine is widely applied for electrical insulation parts, insulator, anti-vibration pad, sealing element, auto spare parts, shoe sole and galoshes, etc.

Rubber injection molding machine has the main characteristics as follows:

1. The simple working process can realize short vulcanization of rubber products and shorten the

2. The machine can produce rubber products with accurate dimension, high quality and good physical and mechanical properties, which make it suitable for processing rubber products with thick wall.

3. The machine is featured with high rate of certified products and it can produce rubber products with less rough selvedge.

4. It is featured with easy operation, low labor intensity, high mechanization and automaticity.

Plastic pipe extrusion line is to melting and mixing plastic material and extruding through die head and finally cooling and sizing the pipes. It is widely used for producing water pipe, oil pipeline, blow-off line, etc.

Plastic pipe extrusion line has the advantages of high automaticity, easy operation and stable and reliable production. The pipes produced by the plastic pipe extrusion line are featured with moderate rigidity, good flexibility, creep resistance, environment stress crack resistance, etc.

Plastic pipe extrusion line is composed of control system, extruder, die head, cooling system, dragger, planetary cutter, etc.

The annual output of rubber injection moulding machine is 120 sets per year; and the annual output of plastic pipeline extrusion line is 50 sets per year.

We also provide pre-sale service such as introduction to manufacturing sequences, workshop planning and technology consulting.

The delivery time of standard equipment is one month; delivery time for non-standard equipment is 3 month; the delivery time for dedicated device is 4 to 5 month.

The warranty period is one year; during this period, we can change spare parts for free except for quick-wear part.

We provide customized service as per customer requirements and investment planning and total solution for customers on turn-key basis as well as operation training. We do OEM for France REP Company and Germany KRAUSSMAFFEI Company.